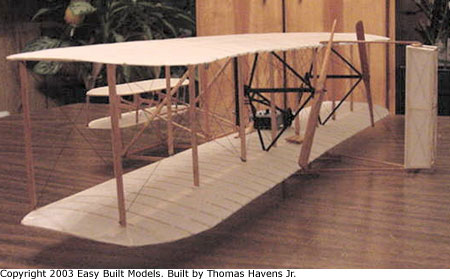

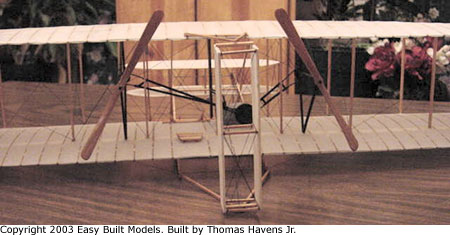

This 1:20 scale model kit of the first engine-powered flying machine to make a successful flight commemorates the dawn of powered flight. On December 17, 1903 Orville Wright launched the Wright Flyer I from a sand dune known as Big Kill Devil Hill near Kitty Hawk, North Carolina. The flight lasted 12 seconds and a distance of 120 feet. The Wright Flyer I was the culmination of years of research and testing during which brothers Orville and Wilbur Wright designed and built all the components of the Flyer including the propellers and engine.

This LASER CUT kit is popular for school projects in both history and science since it is an accurate scale model of the original airplane which is on display in the Smithsonian Institution Museum of Air and Space.

Wright Flyer Building Instructions

Click on the Instructions for step-by-step instructions with 38 photographs to guide you through the building process.

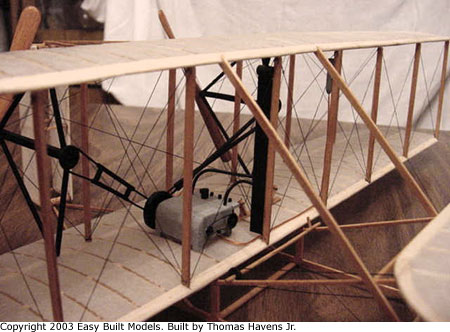

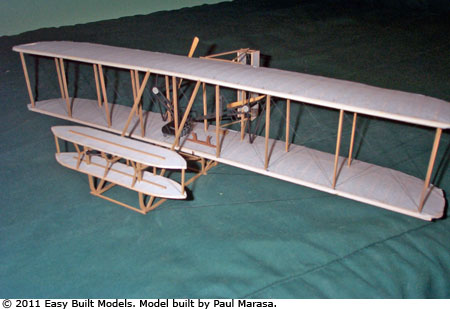

This kit includes laser-cut balsa parts, balsa strip wood, wire, thread, and Easy Built Lite tissue covering. Also includes a laser-cut pilot profile in the prone position, and laser-cut engine assembly. To build this kit you will need a building board, hobby knife, glue, thread, and fine sandpaper. This kit is completely laser-cut, saving hours of time cutting out parts. The builder determines the level of detail for this model and may need to supply additional materials.

CUSTOMER BUILDS & INFO

This newly completed model built by Brad Kyle shows off the laser-cut pilot profile included with the kit.

"Finished my flyer and added the launch rail and catapult. It looks as close as I could get it. Thanks for all this fun." - Dean Wilson

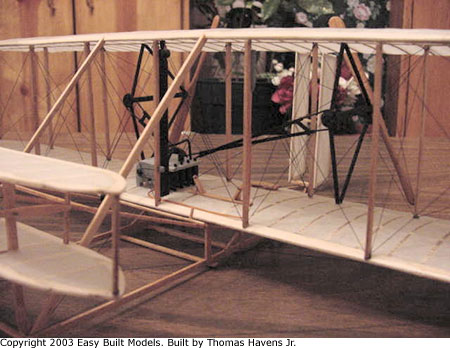

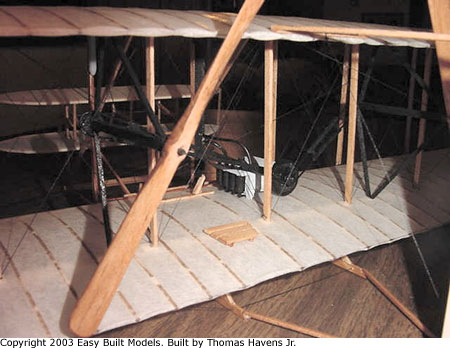

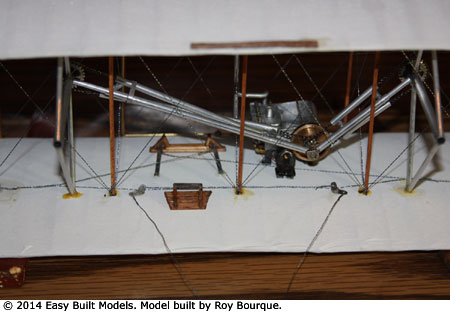

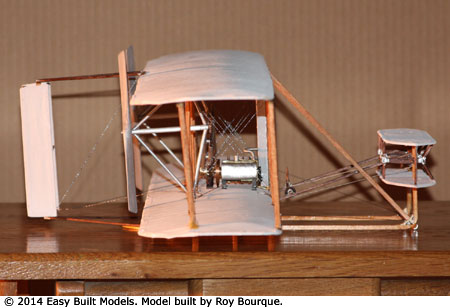

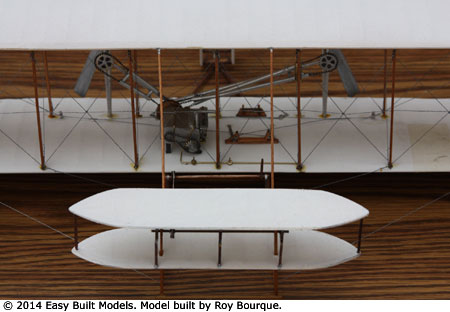

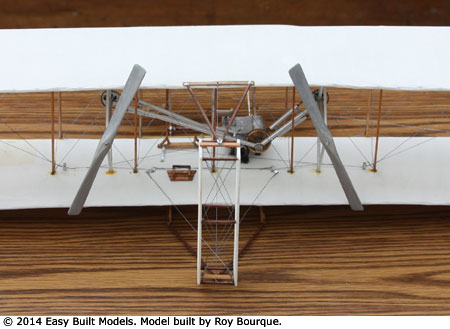

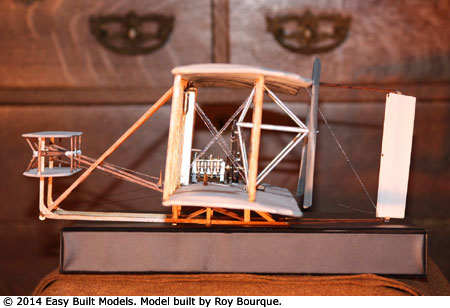

"Attached are photos of the Wright Flyer D-10LC model kit that I built. I built the wooden wings and assembly from the kit but chose to build the metal parts out of metal stock. A wood stain was used to darken the balsa wood. I used a print of the wright flyer for details. I used a small chain necklace for the chain. I used the same necklace to attach links for the rigging. I used silver embossing thread for the wire rigging. I had a discarded instrument that I recovered gears from and filed them thinner so the chain would fit over them for the sprockets. I used a black magic marker to make the gears look like sprockets. I used wood glue for the balsa wood, thinned Elmer's glue for the fabric covering, and Sinbad super glue for the metal parts. The engine block was made from a shaped pine wood block that was covered with aluminum flashing using super glue to hold it on. Jewelers files were used to shape the intricate metal parts, and a dremel tool with 32nd drill was used for small holes. Surgeons pliers were used to hold small parts while shaping or assembling. I used silver paint to denote metal hinge joints and fine point black magic marker for the pivot points such as in the stabilizer connecting rods and rudder pivots." - Roy Bourque